Functions and characteristics of pressure gauge fatigue test bench

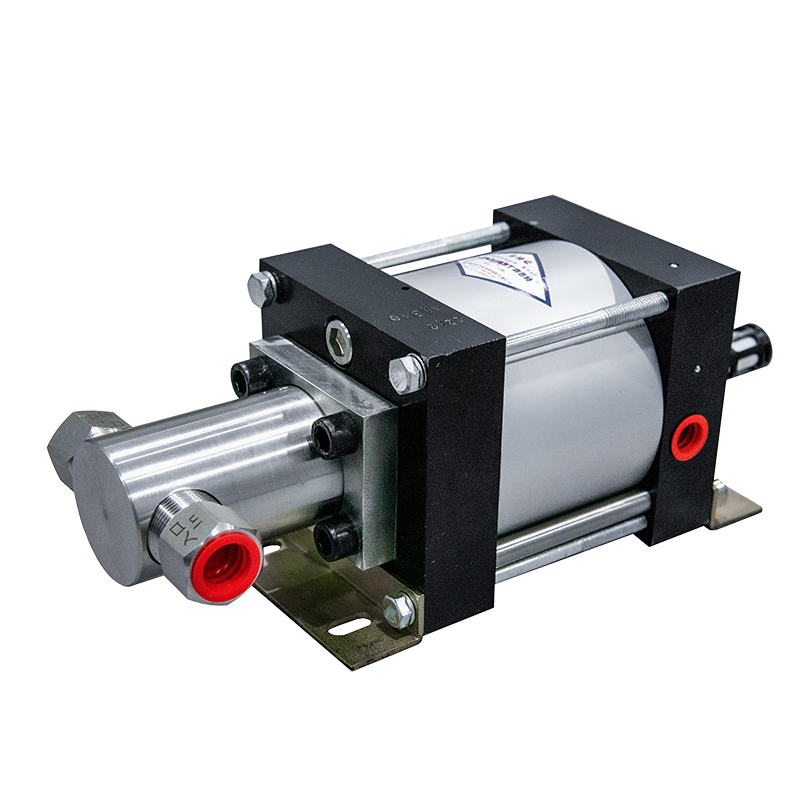

The pressure gauge fatigue test bench is a professional equipment used to test the durability and fatigue performance of pressure gauges, widely used by pressure gauge manufacturers, laboratories, and quality testing institutions. This test bench simulates the working state of a pressure gauge under long-term, high-frequency pressure fluctuations or cyclic conditions. By repeatedly applying pressure changes, the performance stability, lifespan, and fatigue tolerance of the pressure gauge are tested.

The main functions and characteristics of the pressure gauge fatigue test bench

1. Pressure cycle test

The test bench simulates the periodic changes of the pressure gauge in actual use, sets the range of high and low pressure, and repeatedly operates the pressure gauge within a certain pressure fluctuation range to test its performance under long-term repeated loading conditions.

2. Pressure range

The pressure range of the test bench is usually adjusted according to the specific testing requirements of the pressure gauge, and the common testing pressure range ranges from several hundred pascals to tens of megapascals (MPa). At the same time, the test bench is equipped with a precise pressure control system to ensure that the applied pressure meets the standard testing requirements.

3. High frequency cycling capability

The pressure gauge fatigue test bench can achieve high-frequency pressure cycling, and can generally simulate thousands to millions of pressure changes to evaluate the performance of the pressure gauge under high-frequency fatigue conditions, and detect whether it will experience errors, damage, or failure.

4. Multi station testing

The pressure gauge fatigue test bench usually supports multiple stations for simultaneous testing, and can test multiple pressure gauges simultaneously. It can improve testing efficiency and meet the fatigue testing needs during mass production in factories.

5. Data collection and analysis

The test bench is equipped with a data acquisition system that can monitor and record the response data of the pressure gauge in real time during the testing process. By analyzing parameters such as pressure, time, and fatigue cycle times, the lifespan, accuracy drift, and performance changes of the pressure gauge can be evaluated.

6. Protection mechanism

Test benches are usually equipped with safety protection functions to prevent damage to equipment or test samples in the event of overvoltage, failure, etc. Set pressure overload protection and automatic shutdown function to ensure safe and reliable testing.

Pressure gauge fatigue test bench

Pressure gauge fatigue is mainly used by pressure gauge manufacturers to test the fatigue performance of pressure gauge products during research and production processes, ensuring that product quality meets standard requirements. Laboratories and testing institutions are used to conduct fatigue tests and quality assessments on various pressure gauges, and issue third-party testing reports. In the fields of industrial petroleum, chemical, aerospace, etc., it is required that pressure gauges work stably for a long time in harsh or high-pressure environments, and fatigue testing is a key step to ensure their reliability. The relevant standards for fatigue testing of pressure gauges usually include ISO 4064, performance testing standards for pressure gauges and pressure sensors. GB/T 1226, Pressure gauge testing method for Chinese national standards. ASTM D1598, Fatigue testing standards for pressure gauges and pressure devices.

The pressure gauge fatigue test bench is a key testing equipment that ensures the long-term stable operation of pressure gauges under high-frequency pressure changes. By simulating pressure fluctuations under real working conditions, the test bench can effectively evaluate the lifespan, accuracy, and fatigue resistance of pressure gauges, ensuring their reliability in various industrial and engineering applications.

The main functions and characteristics of the pressure gauge fatigue test bench

1. Pressure cycle test

The test bench simulates the periodic changes of the pressure gauge in actual use, sets the range of high and low pressure, and repeatedly operates the pressure gauge within a certain pressure fluctuation range to test its performance under long-term repeated loading conditions.

2. Pressure range

The pressure range of the test bench is usually adjusted according to the specific testing requirements of the pressure gauge, and the common testing pressure range ranges from several hundred pascals to tens of megapascals (MPa). At the same time, the test bench is equipped with a precise pressure control system to ensure that the applied pressure meets the standard testing requirements.

3. High frequency cycling capability

The pressure gauge fatigue test bench can achieve high-frequency pressure cycling, and can generally simulate thousands to millions of pressure changes to evaluate the performance of the pressure gauge under high-frequency fatigue conditions, and detect whether it will experience errors, damage, or failure.

4. Multi station testing

The pressure gauge fatigue test bench usually supports multiple stations for simultaneous testing, and can test multiple pressure gauges simultaneously. It can improve testing efficiency and meet the fatigue testing needs during mass production in factories.

5. Data collection and analysis

The test bench is equipped with a data acquisition system that can monitor and record the response data of the pressure gauge in real time during the testing process. By analyzing parameters such as pressure, time, and fatigue cycle times, the lifespan, accuracy drift, and performance changes of the pressure gauge can be evaluated.

6. Protection mechanism

Test benches are usually equipped with safety protection functions to prevent damage to equipment or test samples in the event of overvoltage, failure, etc. Set pressure overload protection and automatic shutdown function to ensure safe and reliable testing.

Pressure gauge fatigue test bench

Pressure gauge fatigue is mainly used by pressure gauge manufacturers to test the fatigue performance of pressure gauge products during research and production processes, ensuring that product quality meets standard requirements. Laboratories and testing institutions are used to conduct fatigue tests and quality assessments on various pressure gauges, and issue third-party testing reports. In the fields of industrial petroleum, chemical, aerospace, etc., it is required that pressure gauges work stably for a long time in harsh or high-pressure environments, and fatigue testing is a key step to ensure their reliability. The relevant standards for fatigue testing of pressure gauges usually include ISO 4064, performance testing standards for pressure gauges and pressure sensors. GB/T 1226, Pressure gauge testing method for Chinese national standards. ASTM D1598, Fatigue testing standards for pressure gauges and pressure devices.

The pressure gauge fatigue test bench is a key testing equipment that ensures the long-term stable operation of pressure gauges under high-frequency pressure changes. By simulating pressure fluctuations under real working conditions, the test bench can effectively evaluate the lifespan, accuracy, and fatigue resistance of pressure gauges, ensuring their reliability in various industrial and engineering applications.

CONTATE-NOS

Utilize o formulário abaixo para entrar em contato.

Caso necessite de uma resposta entraremos em contato o mais breve possível.